Frequently Asked Questions

Why should my parts be micro drilled? Couldn't they be laser or EDM drilled?

Laser or EDM drilling is limited in a number of ways: there are particular material restrictions, as well as hole quality and hole depth limitations. Additionally, the material can become compromised because of the intense heat generated by EDM and laser drilling. For these reasons and others, we prefer mechanical drilling.

What is your privacy policy?

RIFF Company, Inc. will collect no personal information about you when you visit our website unless you choose to provide that information to us. Any personal information submitted through this website will be for RIFF's internal use only and will not be shared with any third parties.

Is there a maximum number of holes that can be drilled?

No. We have done parts that include 14,000 holes in a 3/4" square area.

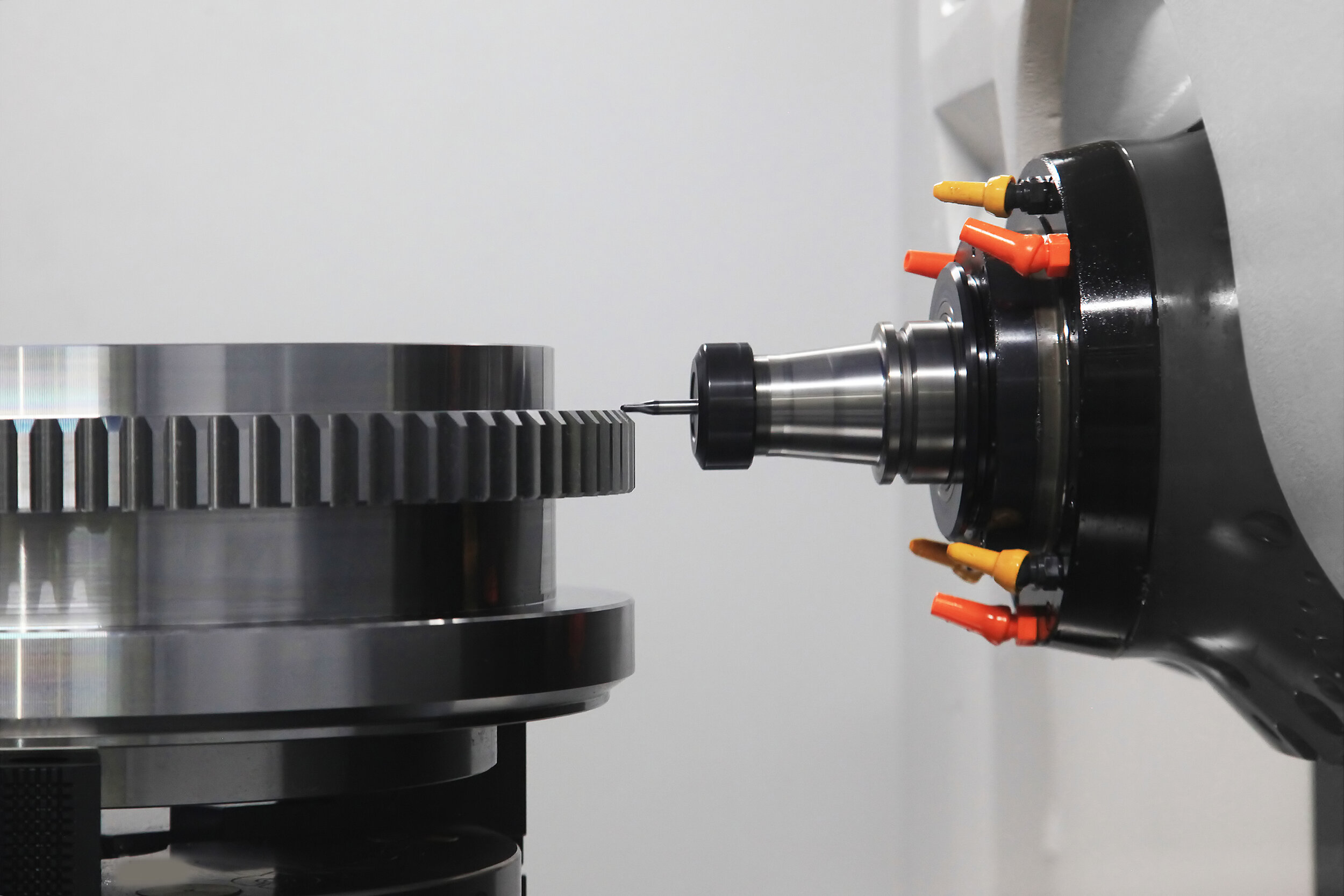

What are your manufacturing capabilities?

RIFF Company provides burr-free micro drilling, vertical machining and surface grinding.

Please see our facilities list for a more complete overview of our capabilities. We are continually updating our facilities to provide greater accuracy and increased capabilities.

Do you provide part samples?

We can provide samples to check hole quality and material integrity. Contact us for details.

What is your standard turnaround time?

Many of our customers have found themselves facing shorter and shorter development time frames. We respond to their need for quick turnarounds by using state-of-the-art equipment for greater speed, and directly importing drilling hole files, via email or disk, from the customers' computers to our machines.

What are your inspection capabilities?

RIFF's inspection equipment includes a calibration grid plate certified to .000010". We ensure accuracy to ±.0001". RIFF inspects holes at a 1,000 magnification with a video edge detection process, and measures parts up to 12" x 18".

100% of the holes we drill are checked for both location and diameter. Verification documentation, either on disk or as hard copy, can be provided to confirm that the holes and hole pattern meet specification requirements. Please see our Facilities List for a listing of our current inspection equipment.